CPI

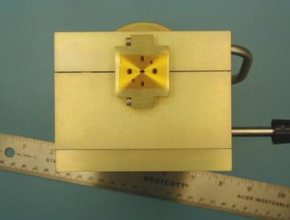

CPI VJB2002 Closed Loop Heat Exchanger - Water to Air Laboratory Chiller

Request a quote at Contact@orbitalconnect.com or +1.888.315.9545

Model VJB2002 is a refrigerated, recirculating water conditioning heat exchanger specifically configured for operation with Extended Interaction Klystrons (EIKs). This easy to use chiller is optimized for the demanding purity and cooling requirements of water cooled EIKs. It features a robust refrigeration system designed for continuous operation, providing accurate control of temperature and ensuring water purity needs are met. With a focus on reduced maintenance, the chiller comes with a level indicator and built-in funnel to make filling easier. The integrated air filter is located behind an easy to remove condenser grill for quick and simple cleaning to optimize chiller performance and maximize operational life. When purchased as part of a system, the chiller comes pre-configured to match the EIK cooling needs and interlocked with the power supply unit to ensure safe operation of the EIK. Fault conditions of out-of-range temperature, flow or conductivity will provide an open circuit signal to the power supply that will shut down the operation of the EIK for fault resolution.

Functions:

- A pump in the chiller circulates water throughout a closed-loop system. Heat from various sources is conducted into the water and a heat exchanger in the chiller transfers the heat into the surrounding air

- A partial flow filtering system maintains water purity by removing particulates and regulating the conductivity (resistivity) of the water

- The chiller displays process water temperature, pressure, flow rate and resistivity. Additionally, these parameters are monitored to warning and trip level ranges

- An EIK power supply interlock function enables EIK high voltage operation when cooling system parameters are within correct operating values

Model VJB2002 is a refrigerated, recirculating water conditioning heat exchanger specifically configured for operation with Extended Interaction Klystrons (EIKs). This easy to use chiller is optimized for the demanding purity and cooling requirements of water cooled EIKs. It features a robust refrigeration system designed for continuous operation, providing accurate control of temperature and ensuring water purity needs are met. With a focus on reduced maintenance, the chiller comes with a level indicator and built-in funnel to make filling easier. The integrated air filter is located behind an easy to remove condenser grill for quick and simple cleaning to optimize chiller performance and maximize operational life. When purchased as part of a system, the chiller comes pre-configured to match the EIK cooling needs and interlocked with the power supply unit to ensure safe operation of the EIK. Fault conditions of out-of-range temperature, flow or conductivity will provide an open circuit signal to the power supply that will shut down the operation of the EIK for fault resolution.

Functions:

- A pump in the chiller circulates water throughout a closed-loop system. Heat from various sources is conducted into the water and a heat exchanger in the chiller transfers the heat into the surrounding air

- A partial flow filtering system maintains water purity by removing particulates and regulating the conductivity (resistivity) of the water

- The chiller displays process water temperature, pressure, flow rate and resistivity. Additionally, these parameters are monitored to warning and trip level ranges

- An EIK power supply interlock function enables EIK high voltage operation when cooling system parameters are within correct operating values